A plastic inspection chamber, also known as manholes or plastic access chamber, are a key component of underground drainage systems. The plastic inspection chamber provides access for inspection, cleaning, testing, and maintenance of the drainage system.

The plastic drainage inspection chamber is typically a cylindrical or rectangular structure that is installed at points where there are changes in the direction, gradient, or diameter of the drain pipes. The plastic drainage chambers can also be installed at regular intervals along straight runs of drain pipe to facilitate access.

Plastic inspection chambers are made from durable, lightweight materials like PVC or polypropylene. PVC and PP inspection chamber are resistant to corrosion and chemical attack, making them suitable for use in a wide range of environments. They are also easy to install and require little maintenance.

The design of a plastic inspection chamber typically includes a base, riser sections, and a cover. The base includes inlets and outlets for the drain pipes, and the riser sections are used to adjust the height of the chamber to match the ground level. The cover is designed to withstand loads from traffic and prevent unauthorized access.

Plastic inspection chambers are available in a range of sizes and configurations such as 450mm plastic inspection chamber and 600mm plastic inspection chamber to suit different applications. They must be installed and used in accordance with local building codes and regulations.

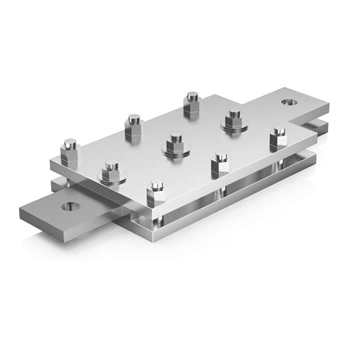

Natural Rubber Bearing

Natural Rubber Bearing

Lead Rubber Bearing

Lead Rubber Bearing

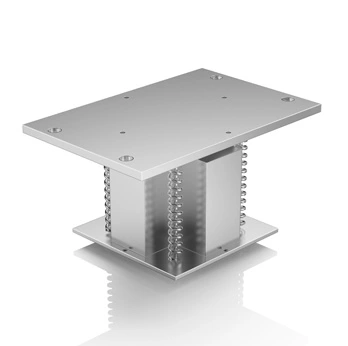

High Damping Rubber Bearing

High Damping Rubber Bearing

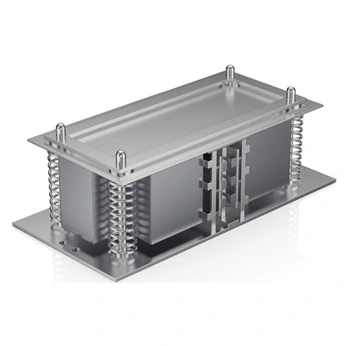

Elastic Bearing

Elastic Bearing

Friction Pendulum Seismic Isolation

Friction Pendulum Seismic Isolation

Simple Support For Village And Town Houses

Simple Support For Village And Town Houses